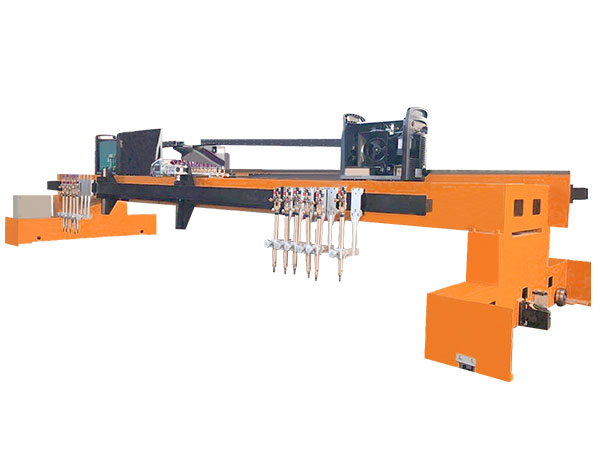

Model: PE-CUT-3260

Perfect laser straight gantry CNC cutting machine with bilateral drive, stable operation, good configuration and high efficiency, can be used for a variety of carbon steel, manganese steel and other metal materials, large and medium-sized steel plate pumping strip cutting.Cutting method can choose the single flame cutting, plasma cutting or flame plasma cutting with straight cutting. Optional multiple torch system and capacitive flame automatic heightening system.

Perfect laser has been committed to providing customers with cost-effective CNC cutting equipment, professional services to save your worry and rest assured, is your best choice.

1.Highly anti-interference: the use of CNC control system by independent research and development , with PLC input and output control, making the electrical system has good stability and highly anti-jamming capability to ensure that no plasma interference.

2.Simple automatic programming: Perfect laser independent research and development of automatic programming system is easy to learn, non-professional operators can quickly grasp the operating skills after 2-3 days of video training.

3.Smooth operation: professional rail, planetary gear reducer, Japan imported all-digital AC servo motor or German white Ge la stepper motor, the whole machine running smoothly, can instantaneously adjust the speed and the acceleration cycle is short and smooth.

4.Equipped with dust collector:gather debris on the surface of the rails at any time, to ensure that the operating platform is clean and tidy.

5.With the lifting platform: the use of aluminum alloy structure, lifting direction with through-type lift and use the ball screw to enhance.

Suitable materials

stainless steel, manganese steel, non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel) and other large, medium and small plate of metal materials.

Suitable industry

petrochemical, power equipment, heavy machinery, shipbuilding industry, boiler manufacturing, machinery manufacturing, aerospace, vehicle manufacturing.

Gauge (mm) | 4000 (can be widened according to customer requirements) | |

Track length (mm) | 8000 (can be extended according to customer requirements) | |

Effective cutting width (mm) | 3200 | |

Effective cutting length (mm) | 6000 | |

Driving mode | Bilateral drive | |

Speed range (mm / min) | 0-5000 | |

Horizontal longitudinal drive system | Three - phase hybrid stepping drive system | |

Number of CNC torch systems (pair) | 1 (single flame or single plasma) | |

Straight cutting torch system quantity (pair) | 9 (can be allocated) | |

Shunt row (group) | 9 + 1 | |

Flame cutting thickness(mm) | 5-180 | |

The plasma cutting thickness | Determined by the plasma power selected by the user | |

Automatic height adjustment system (set) | arc pressure automatic adjustment | 1 |

Electric lift | 1 | |

Automatic ignition / arc device | 2 | |

Flame cut gas | oxygen + acetylene / propane / natural gas / gas | |

Control system (permanent free upgrade) | Beijing Star Dart / Shanghai traffic University / US Haibao, etc. (optional) | |

Plasma Power | US Haibao / Germany Kelbe / US Pegasus, etc. (optional) | |

This is Helen from Perfect Laser. Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net