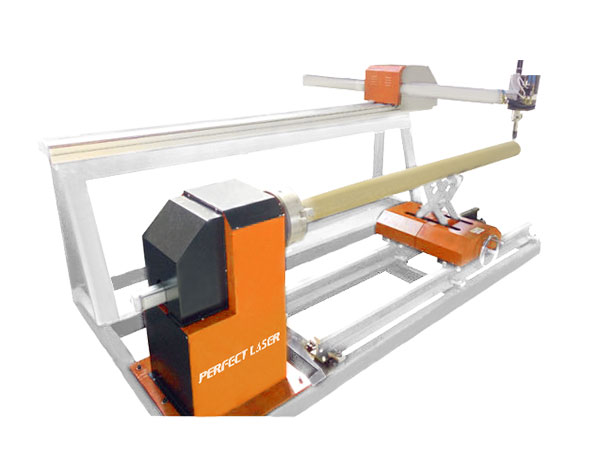

Model: PE-CUT-D1 D2

Perfect laser tube and board cutting machine is absorbed the advantages of many domestic CNC cutting machine, and to improve the integration of green low-carbon, automated design concept.Finally introduce this machine with cost-effective, high-profile, low-power automatic calculation and cutting equipment, automation high degree of cutting speed and perfect cutting effect.

It is widely used in building structure, chemical shipbuilding, and mechanical engineering, and so on. It has excellent working effect, such as intersecting line hole, intersecting line end and elbow (shrimp festival).

1.Smooth operation: the use of brand-driven motor, optional stepper motor or servo motor, 6mm channel welded with the machine, precise ball screw to ensure a more stable machine running, higher accuracy.

2.High efficiency: high cutting speed and high efficiency,the cutting slit is small and not easy to deform. The cutting surface is smooth and beautiful, you can cut pipe, square tube and other special-shaped tube, or metal plate, this process without re-installation of the tools.

3.High precision machining: equipped with automatic tracking and adjusting system, can easily complete the distortion of the deformation of the material processing to ensure reliable positioning of the processing operations to replace the traditional drilling and sawing, will not produce deformation of the material.

4.Intimate service: details change the fate .At the time that Perfect laser pursuing the product quality, will also let the sales services runs through our lives, and strive to allow customers to understand the product timely.

Applicable materials

Metal sheet and pipe material. Particularly suitable for stainless steel plate, carbon steel, alloy steel, copper, aluminum, rare metal, ceramic, silicon, diamond and other materials cutting.

Applicable industries

Metal structure production, all kinds of metal products, advertising signs, electrical cabinets, kitchen appliances, precision machinery and equipment, steam this accessories, glasses, craft gifts, lighting hardware, precision parts and other industries.

Cutting diameter range | 60mm - 300mm |

Flame cutting wall thickness | 5mm - 50mm |

The plasma cutting thickness | depends on the size of the plasma power supply |

Effective cutting length of the work piece | 3000mm |

Cutting speed | flame speed within 700mm / min ,The plasma cutting speed depends on the size of the plasma power supply |

Pipe carrying weight | ≤ 400KG |

Moving speed | 10mm / min - 4000mm / min |

Movement axis X axis (transverse axis) | Pipe rotation axis |

Movement axis Y-axis (longitudinal axis) | The torch moves horizontally along the pipe axis |

Movement axis Z axis (torch lift shaft) | Torch lifting shaft |

Steel tube drive mode | Electric drive chuck rotation to match the longitudinal equipment operation |

Cutting method | plasma cutting, flame cutting (depending on customer requirements) |

Lifting mode | Plasma (automatic arc pressure elevation) Flame (electric lift) |

Cutting function selection | intersecting line cutting / tube board one cut |

Drive mode | precision gearbox and gear drive |

Drive motor | Panasonic A5 drive / motor |

Pipe diameter | 0.1r / min - 25r / min |

Reset accuracy | ± 0.2mm |

Cut the gun lift stroke | 105mm |

Chuck size | 250mm |

This is Helen from Perfect Laser. Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net