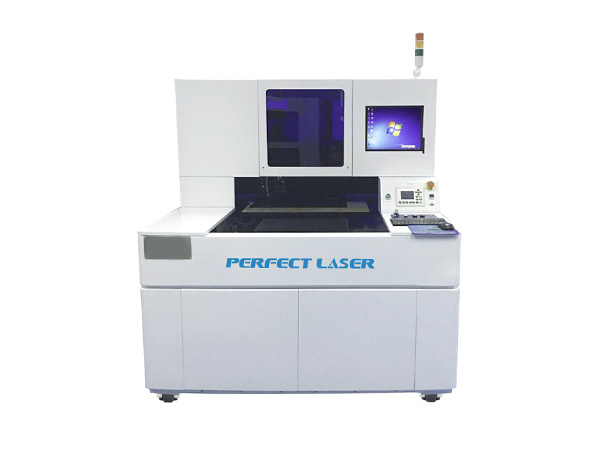

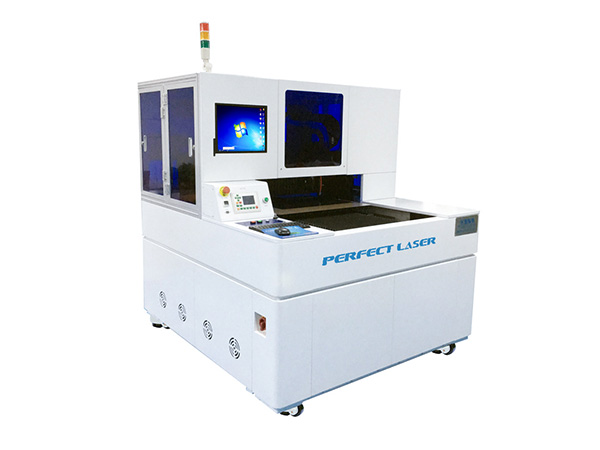

Model: PEG-1090

Industrial laser drilling machine PEG-1090 is mainly composed of marble frame sheet metal, moving gantry module, vacuum adsorption platform, CCD alignment mechanism, panel placement fixture, laser system, manual discharge platform, electric control system and so on.

The high energy and high precision laser is used to drill the glass material, the high-definition image alignment and the professional customized operating software control system make the production efficiency higher, the repeated positioning is more accurate, and the operation is easier.

1. Selected high-quality materials, high-quality lasers with long service life, high electronic optical conversion rate and good beam quality.

2. Laser drilling machine the processing method is to directly vaporize the glass material to cut, without secondary processing to achieve the desired effect.

3. No water cooling processing, environmental pollution, no consumables. Cut edges: No grinding required.

4. The laser glass cutter supports 7 days 24 hours operation, long-term to use and good stability.

5. Laser glass cutter the processing speed is fast, the efficiency is high, the edge and the heat influence is small, low. the power consumption.

6. Laser glass cutting machine adopts laser non-contact processing, no hard force damage to the processed products.

7. Simple operation, no special requirements for the operator, a little training can be carried out.

8. High-definition image alignment and professional customized operating software control system, repeated positioning more accurate.

The laser glass cutting machine is widely used in instrument glass, photovoltaic glass, mobile phone glass, medical instrument, vehicle display, panel display glass and other industries.

Item | Main Technical Data | |

Laser system | Laser type: Fiber Laser | 30w |

Wavelength :532NM Gr(Specialized for high-grade optical film) | Frequency: 150KHz | |

Maximum power output:35W | Output power stability:±5% | |

optical quality:M<1.3 LD | Module lifetime:>10000H | |

Microscopic imaging system | Model:Ewin lens-1 | Imaging Lens:IR anti reflection film |

CCD Pixel:30WPixel (Field of View: 6.4mm*4.8mm Resolution:5um) | ||

Display:17inch 1920*1080mm | Image capture card brand and model :Maim | |

CCD brand: Can definitely order products | ||

Software system | Control Function: 1.Laser energy, frequency, pulse width regulation storage | 2.Table movement, processing state parameter display |

3.Microscopic imaging adjustment | 4.Store100processing parameters | |

5 Computer:Standard 4U industrial chassis,with 300W ATX Industrial power supply, 15CPU-3470 | ||

Structure of machine | Materials:Marble + sheet metal steel frame | |

Work table size:1000mm*900mm | XY axis travel:1000mm*900mm | |

Z axis travel:80mm | XYZ axis movement speed: Maximal speed :210mm/s Minimal speed:2mm/s | |

Manual fine-tuning:0.25mm/260 degree | Working speed:500mm/s | |

Working depth:<1.5mm | XYZ axis moving accuracy:±0.008mm | |

XYZ axis repeated accuracy:±0.006mm | Platform surface: Vacuum suction of aluminum plate for high purity cutting | |

XY axis motor:linear motor | Motion control card brand and mode:Gugao | |

Guide screw type:Taiwan Shangyin V15 model P class WIWIN double guide ball screw | ||

Exterior paint tint: gray ribbon/opalescent oil(Dustless type) | ||

Operating keyboard function | 1. safety light grid | |

2. CCD Illumination light brightness adjustment | ||

3. Turn on the main power switch | ||

4. Run start button, emergency stop switch | ||

Installation environment Input power:single phase alternating current 220V50-60Hz10A | ||

Humiture:25℃=1℃,60% | ||

This is Helen from Perfect Laser. Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net