1592359105.jpg)

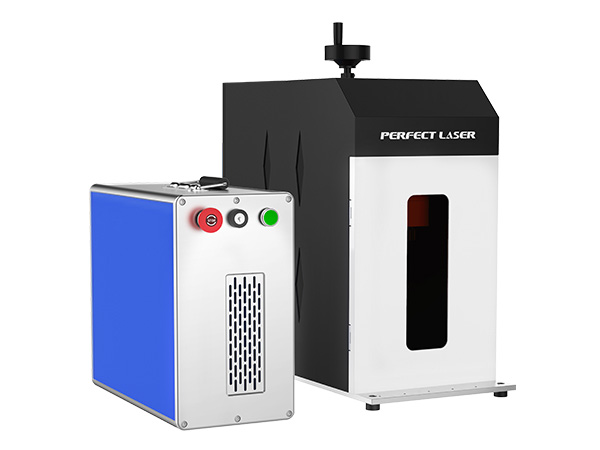

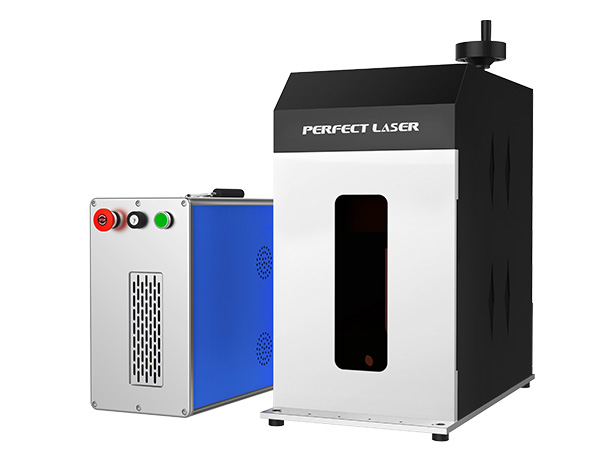

Model: PEDB-400BII

Perfect Laser 's the metal laser etching machine uses laser technology is more advanced in the world, and developed into a new generation of closed type optical fiber marking machine. The output of fiber laser, high life stable devices, with the appearance of new, unique structure, simple operation, high modulation frequency, marking speed, high precision, stable performance and other advantages, this fiber laser etching machine can be widely used as a permanent marker of various kinds of metal and non-metallic surface.

1. High quality imported fiber laser, the adaptability of the material is very wide, you can make a very fine mark on the surface of a variety of materials, and cutting durability of the metal laser etching machine is very good.

2. The metal laser etching machine is easy to operate, simple, fast, efficient, according to their wishes to design their desired logo, clear and convenient, high satisfaction.

3. The speed block of the closed fiber marking machine is 2-3 times of that of the traditional marking machine.

4. All parts of the laser coding machine are integrated, compact, firm, light, compact, and better performance.

5. Closed fiber laser etching processing, no pollution source, energy saving, environmental protection, no supplies, to save costs for customers

6. Closed fiber laser coding machine without any maintenance, long service life, small size, easy to move, can change the position with the environment, suitable for harsh environment work.

This metal laser etching machine is widely applied in all kinds of metal and coating, sanitary ware, glasses, watches, auto parts, plastic material, PVC pipe, IC chip, plastictranslucent keys, digital products, jewelry, measuring and cutting tools, electronic components, precision machinery, building materials, pipes, hardware tools, hardware accessories. Equipment shell, food, cosmetics, assembly line operation, etc.

Model No | PEDB-400BII fiber marking machine | |||

Type | Desktop | |||

Computer | Not includes PC | |||

Laser Source | ||||

IPG Series | Pulsed, High Energy Ytterbium Fiber Lasers | |||

Mode of operation | Pulsed | |||

Polarization | random | |||

Nominal average output power | 10W - 30W For PEDB-400B | |||

Central emission wavelength | 1064 nm ,Q-switched operation Output power adjustment range 10%-100% | |||

Emission Bandwidth (FWHM) | <10 nm | |||

Long-term average power instability | <5% | |||

Pulse width(FWHM) | 100 ns | |||

Laser switching ON time | 180 μsec | |||

Laser switching OFF time | 180 μsec | |||

Pulse Repetition Rate* kHz | 20-80 kHz | |||

Energy per pulse (PRR = 20 kHz) | 0.95 mJ | |||

Typical beam quality, M2 | <1.8 | |||

Output fiber delivery length | 3m | |||

Operating voltage | 220V | |||

Max. Power consumption | 600W | |||

Net Dimensions | 70*20*50cm | 58*22*50cm 80*38*72cm | 70*20*50cm | 143*62*101cm |

Net Weight | 44 kgs | 53 kgs | 44 kgs | 130 kgs |

Gross Weight | 60 kgs | 70 kgs | 60 kgs | 200 kgs |

Laser system | ||||

Scanning Speed | 0-7000mm/s | |||

Marking Speed | 0-5000mm/s | |||

Marking size | 110mm×110mm (F-theta 160) | |||

Spot size | ≤ 40 micron (F-theta 160) | |||

Cooling unit | Air cooled | |||

Red point laser | 650nm , visible red light for marking guide | |||

Continuous working time | ≥16h | |||

Humidity | 45~85% (no condensation) | |||

Operating temperature | 0~40℃ | |||

Control units | Laser Mark (English Version) | |||

This is Helen from Perfect Laser. Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net