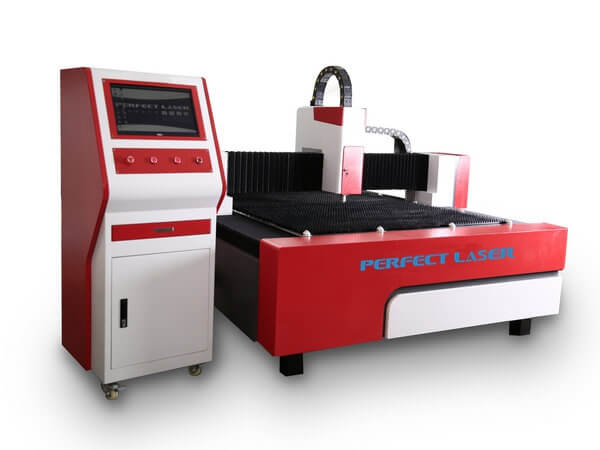

Model: PE-F300-3015

1. The fiber optic laser cutter adopts world famous Germany fiber laser source and American imported laser cutting head & dynamic focus system, and fiber optic laser cutter can cut and punch different kinds of metal materials with high precision and high speed.

2. Since laser is transmitted by fiber, fiber optic laser cutter doesn't need to maintenance, and also doesn't need to adjust the laser optical path at all. The fiber optic laser cutter greatly reduces the machines' fault rate and prolongs the working life.

3. The fiber cutter machine has large cutting area from 1.5M to 3M, and the laser cutter for metal can also meet the demands of various kinds of metal processing.

1) Extremely high photoelectric conversion efficiency, extremely low use cost:

The fiber cutter machine photoelectric conversion efficiency up to about 30%, is 3 times the CO2 laser cutting machine, greatly reducing the power consumption of the entire machine, a substantial saving in the cost of use.

2) Excellent stability, extremely low maintenance costs:

The use of German fiber laser, Panasonic Japan servo motor, the United States imported laser cutting head, the key components of product quality and safety protection, the life of laser cutter for metal up to 100,000 hours. Double-clad active optical fiber eliminates the need to adjust the optical path and eliminates the need for reflective lenses, saving product maintenance costs.

3) Perfect beam quality, fast cutting speed:

Top beam quality, less focused spot, finer cutting lines, faster cutting speeds, and better cutting results. The cutting surface of the laser cutter for metal is smooth and beautiful without secondary processing.

4) Operational training, easy to use:

Perfect Laser provides comprehensive pre-sales support, on-sale service and after-sales training. According to the customer's actual cutting demand, it specifies a personalized laser cutter for metal operation instructions program to ensure that customers grasp the basic theory of laser cutter for metal in a short time, Safety protection measures and equipment maintenance techniques

1. Applicable materials: 300w fiber cutter machine is mainly used for non-contact cutting of metal materials, and it is very applicable to fragile alloys such as carbon steel, stainless steel, aluminum alloy, titanium alloy, aluminum plate, galvanized plate, silicon steel, and pickling plate. Good processing results, so it is also known as metal sheet fiber cutting machine, sheet metal fiber cutting machine, sheet metal laser cutting machine, model laser cutting machine and so on.

2. Industry applications: 300w fiber cutter machine is widely aplied in household appliances, sheet metal processing, precision metal parts (aerospace), electronic appliances, subway accessories, automotive machinery, metallurgical equipment, craft gifts, tool processing, decorative advertising and other industries.

|

Model |

PE-F300-3015 / PE-F300-2513 |

|

Laser Power |

300 Watt Fiber Optic Laser Cutter |

|

Laser Source |

World Famous Germany Fiber laser technology |

|

Laser Type |

Fiber Laser |

|

Laser Technology |

Germany Technology |

|

XYZ Working area |

1500*3000*150 (mm) |

|

Max. Cutting Thickness |

300w (1-3mm Carbon Steel) |

|

Max. Cutting Speed |

0-20 Meters / Min (up to materials) |

|

Laser wavelength |

1070nm |

|

Minimum line width |

≤0.1mm |

|

Location precision |

≤±0.05mm |

|

Re-location precision |

±0.02mm |

|

Max. moving speed |

100m/min |

|

Supporting Format |

PLT, DXF, BMP, AI |

|

Power demand |

380V/50Hz |

|

Cooling Way |

Water Cooling |

|

Worktable max. load |

1000KGS |

|

Transmission Method |

Ball Screw Transmission |

|

Table-driven system |

Japanese Imported Panasonic Servo Motor & Driving System |

|

Focus Method |

Following and Automatic Adjust Focus |

|

Control Method |

Offline Movement Control |

|

Control software |

Perfect Laser Professional Laser Cutting Software |

This is Helen from Perfect Laser. Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net