1736134729.jpg)

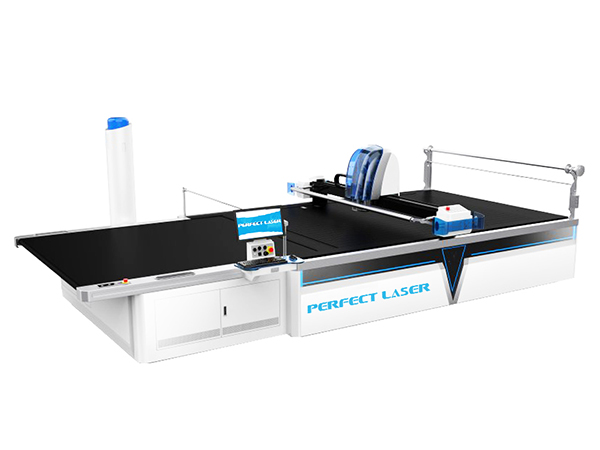

Model: PE-B2025II

The Perfect Laser automatic fabric cutting machine uses CAD data to control the knife’s rotation direction, ensuring precise production of the required cut pieces. Compared with traditional cutting beds, automatic cutting beds have significant advantages in fabric utilization, cutting speed, production cycles and labor costs.

1. With independent software design, automatic cloth cutting machine can be compatible with any CAD format, directly read the layout of the customer's layout.

2. High Production and Work Efficiency: The automatic cloth cutting machine offers fast speed and high precision, reducing the need for rework and saving time in subsequent processes.

3. High Precision and Safety: Manual cutting is influenced by individual performance, leading to unstable quality with a deviation of about ±1 cm. In contrast, the automatic fabric cutting machine achieves a precision of ±1 mm, with negligible impact on garment sewing.

4. Simple and Efficient Operation: The industrial fabric cutting machine is easy to use and increases efficiency by 10% compared to manual cutting (for knitted fabrics). It enables quick response to delivery deadlines while reducing company management costs.

5. Equipped with an Intelligent Knife Sharpening System: It automatically sets sharpening intervals based on usage time or cutting length, ensuring the blade remains sharp and improving cutting precision.

6. Low Cost of Consumables and Spare Parts: Consumables like overlay film and perforated kraft paper, as well as wear parts such as brushes (with a lifespan of 2-3 years), are cost-effective and easy to maintain. Cutting costs are approximately $0.17 per meter.

7. Improved Production Environment:

The industrial fabric cutting machine reduces dust and noise, delivers neatly cut pieces, optimizes the production environment, and enhances the company’s image.

● Textile and garment industry: such as clothes, shoes, bags, etc.

● Leather products industry: such as bags, belts, wallets, gloves, etc.

● Home decoration industry: such as curtains, sofa covers, bedding and so on.

● Printing and packaging industries: such as labels, posts, packaging boxes, etc.

● Automotive interior manufacturing industry: such as seat cover, steering wheel, etc.

Product name | Automatic Multi-layer Fabric Cutting Machine |

Model | PE-B2025II |

Max Cutting Height | 6cm/9cm(after vac-sorb) |

Cutting Window | Length(no limitation) |

Width(no wider than the fabric width) | |

Working Width(Y) | 1700mm/2000mm/2200mm |

Normal Working Length(X) | 2500mm/3300mm optional |

Electricity | Three phase 380V,50-60Hz |

Power Consumption | 18KW max |

CAD&CAM Connect Way | Ethernet communication/USB Flash memory |

Max Speed of Blade Working | 6000RPM |

Compressed Air | 0.55Mpa 160L/min |

Cutting Speed | 6000mm/min |

Acceleration | 0.8-1g(N/Kg) |

Noise Level | <75dbA |

This is Helen from Perfect Laser. Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net